Introduction

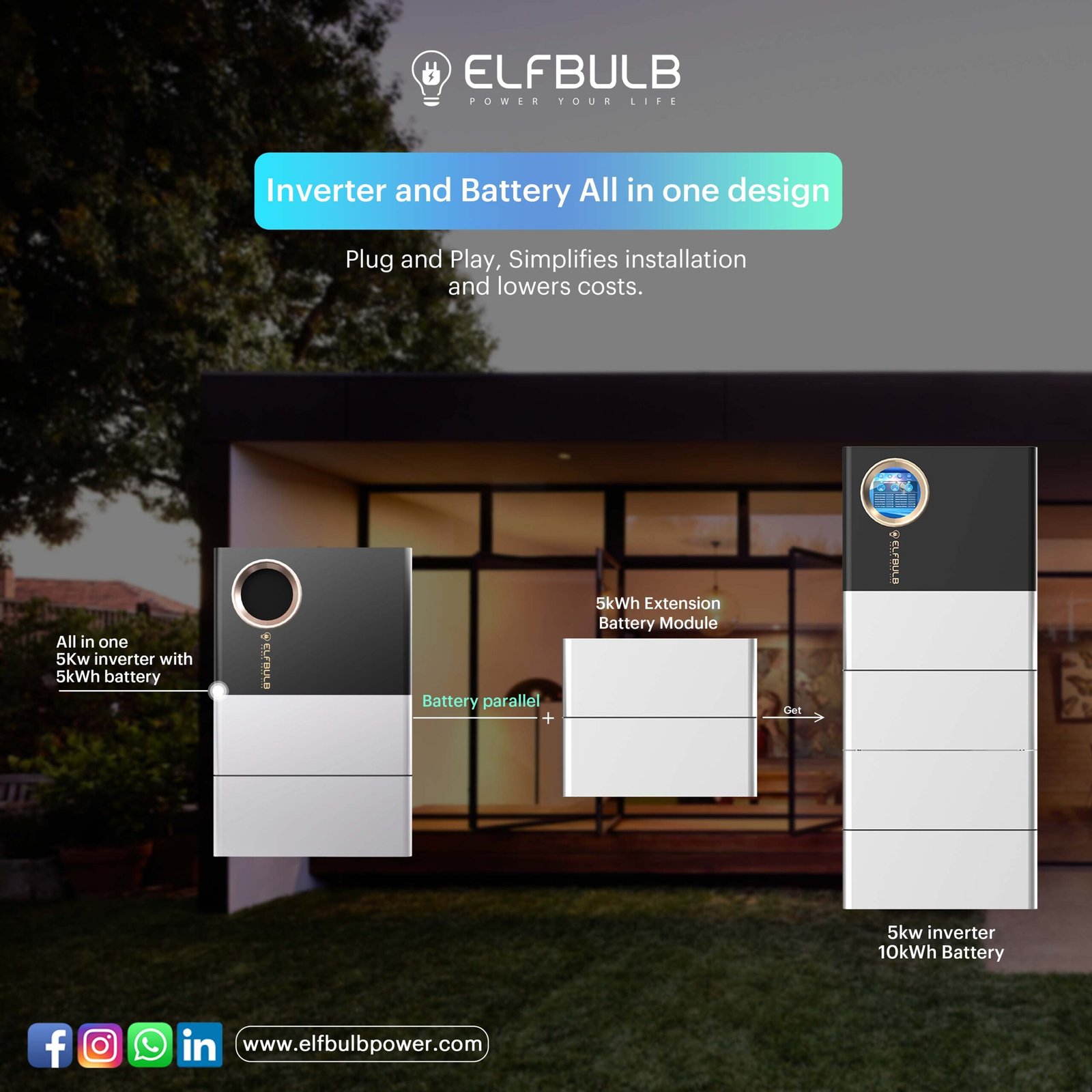

Parallel batteries are a configuration where multiple batteries have their positive terminals connected together and their negative terminals connected together. This method of connection can increase the battery capacity and expand the inverter capacity. However, many people wonder if parallel batteries will discharge evenly.

Answer

In theory, parallel batteries should discharge evenly. This is because each battery is connected to the same voltage, so they should provide current at the same rate. However, in practical applications, there may be some factors that cause uneven battery discharge.

What are the influencing factors of uneven battery discharge?

- Battery Differences: Even batteries of the same model and batch may have slight differences in internal resistance, capacity, and other characteristics. These differences can cause slight inconsistencies in battery performance during discharge.

- Connection Resistance: The connection resistance between the batteries can affect the distribution of current. If the connection resistance is too large, it can cause some batteries to carry more current and discharge faster.

- Usage Conditions: If the batteries in a parallel battery pack are used for different loads, the discharge rates will also vary. For example, if one battery is used to power a high-power device and another battery is used to power a low-power device, the former will discharge faster.

How to extend the equalizing discharge time of parallel-connected batteries?

- Choose Matching Batteries: Use batteries of the same model and batch as much as possible for parallel connection.

- Reduce Connection Resistance: Use high-quality connecting cables and terminals, and ensure that the connections are secure.

- Use Batteries Equally: Avoid using the batteries in a parallel battery pack for different loads as much as possible.

- Built-in Battery Equalizer: This method can reduce the voltage difference, ensure SOC, achieve full charge and discharge, and extend battery life.

Conclusion

In general, parallel batteries should discharge evenly in theory, but there may be some factors in practical applications that cause uneven battery discharge. By choosing matching batteries, reducing connection resistance, using batteries equally, and using batteries with built-in equalizers, the equal discharge time of parallel batteries can be extended.