In the energy storage industry, while round-trip efficiency is a common focal point, there is a “hidden” metric that truly defines the caliber of engineering: System Parasitic Loss (Self-consumption).

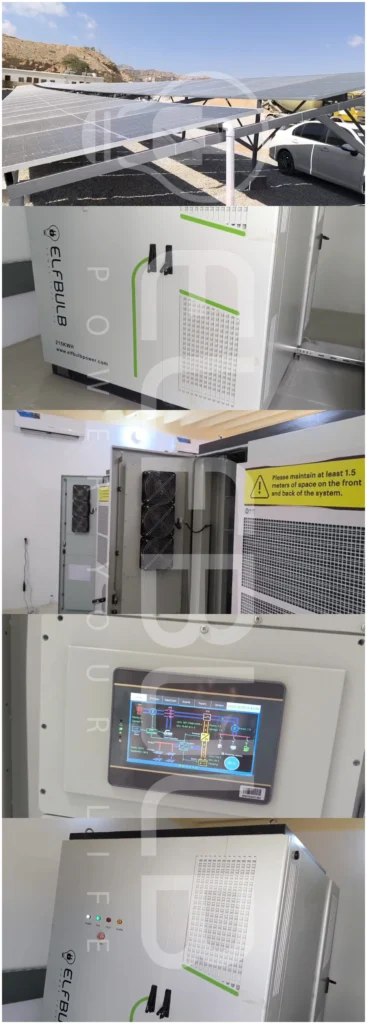

Recently, we successfully commissioned two units of our 197kWh Air-Cooled Energy Storage Systems (ESS), now operating in parallel to power a client’s manufacturing facility. Beyond the successful synchronization, this project highlighted an extraordinary testament to product reliability: a 180-day “unpowered” standby test.

🔋 The 180-Day “Silent Exam”

Due to site construction schedules, these two units remained in storage for six months between factory exit and formal commissioning.

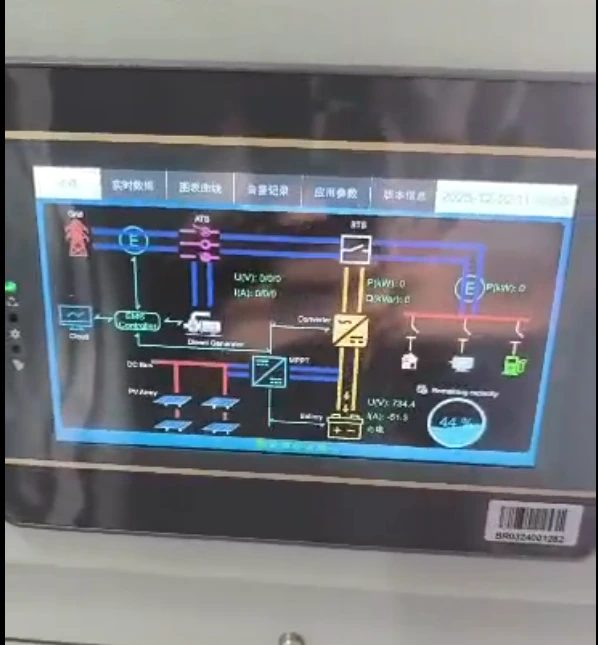

The Field Result: Upon the first power-on by our engineers, the monitoring system showed that the State of Charge (SOC) remained steady at approximately 40%.

🔍 Why Does a 40% Residual SOC Matter?

For an integrated ESS, the SOC retention after prolonged inactivity is a “litmus test” for system-level quality.

- Preventing Irreversible Battery Damage: In systems with high parasitic loads, six months is more than enough to drain the battery to 0%. Such deep discharge can cause irreversible chemical degradation in lithium cells, significantly shortening the system’s lifespan.

- Eliminating Costly Maintenance: If the SOC drops to a critical low, the system may enter a “brick” state where it cannot be started normally. For buyers without specialized high-voltage charging equipment, reviving such a system is both technically complex and financially draining.

🛠 The “Technical Trio” Behind the Performance

This high-score performance is the result of rigorous hardware selection and meticulous electrical design:

- Premium PCS Selection: Our Power Conversion Systems (PCS) are selected for their ultra-low standby power consumption, ensuring the system operates in a “deep sleep” mode that preserves every watt-hour.

- Precision Component Deployment: From the BMS architecture to the high-voltage distribution assembly, every electronic component is strategically placed to minimize leakage current. Our deployment ensures that electrical paths are strictly controlled even when the system is idle.

- Optimized System Integration: The synergy between high-quality hardware and intelligent software logic allows the system to maintain minimal sensory awareness while shutting down non-essential power-consuming circuits.

💡 Quality is Found in the Details

The successful parallel connection and load supply at the client’s factory is more than just a project completion—it is proof of long-term reliability.

Choosing an energy storage system is not just about comparing data sheets; it is about choosing a system designed to endure. Whether delivering high-power output for industrial loads or maintaining integrity during long standby periods, our systems are built to safeguard our customers’ energy investments.